Discover Common Issues in Estimating Flooring Project Costs

Common Pitfalls of Manually Estimating Flooring Costs: What You Need to Know to Avoid Costly Mistakes

Accurate cost projections are the foundation of profitable flooring projects, yet manual estimation often introduces hidden risks. Contractors relying on tape measures and hand-written calculations commonly face errors that erode margins, delay schedules, and frustrate clients. This overview highlights measurement inaccuracies, material waste miscalculations, overlooked expenses, efficiency losses, and software-based solutions. Readers will learn how incorrect area ps, irregular room shapes, conversion mistakes, and skipped double-checks inflate budgets; why underestimating waste and hidden fees drives up costs; how manual methods slow bids and trigger rework; and how flooring estimating software restores precision, saves time, and improves profitability.

What Are the Most Common Measurement Errors in Manual Flooring Estimation?

Manual measurement errors occur when on-site readings, blueprint interpretations, and unit conversions are handled by hand. Inaccurate measurements often stem from human misreads of tape measures, inconsistent rounding, and neglected irregularities. For example, a one-inch miscalculation on a 200-square-foot kitchen can lead to dozens of wasted tiles or costly shortages. Addressing these pitfalls requires disciplined verification steps, but even then, manual processes remain error-prone.

How Do Incorrect Area Calculations Affect Flooring Estimates?

Incorrect area calculations cause material shortages or surpluses that directly inflate budgets. When square footage is under-reported, installers rush to order additional planks mid-project, incurring expedited delivery fees. Over-reporting feedback loops into excess purchases, tying up cash in unused stock and increasing disposal costs. Both scenarios undermine financial control and client trust.

What Challenges Do Irregular Room Shapes Present in Manual Takeoffs?

Rooms with alcoves, angled walls, and bay windows demand multiple segmented measurements that are difficult to aggregate by hand. Estimators often simplify complex shapes into rectangles or triangles, introducing significant variance. This simplification can result in a 5–10 percent deviation on total material requirements, translating into hundreds of dollars in mis ordered supplies. Complex areas thus amplify manual estimation pitfalls.

Why Are Conversion Errors a Frequent Problem in Flooring Estimation?

Conversion errors arise when switching between units—feet to inches, inches to meters, or square feet to square yards—without precise calculations. A misapplied conversion factor (e.g., 9 sq ft in 1 sq yd vs. 10 sq ft in certain contexts) can skew estimates by up to 10 percent. Such misalignments lead to unexpected budget overruns or installation delays as crews await corrected materials.

How Can Lack of Double-Checking Lead to Costly Mistakes?

Failure to systematically verify measurements multiplies the risk of undetected blunders. When estimators skip cross-checking blueprints against on-site dimensions, errors slip through to purchase orders and quotes. Instituting a routine of peer review and digital validation reduces mistakes, yet manual methods rarely enforce these safeguards reliably, compounding financial exposure.

How Does Material Waste Impact Flooring Cost Estimates?

Estimators must account for cutting losses, pattern matching, and future repairs by adding an appropriate waste factor. Underestimating this allowance results in insufficient materials, project stoppages, and rush reorders. Overestimating leads to surplus stock that ties up capital and requires storage or disposal. Applying industry-recommended percentages tailored to material and installation pattern helps balance cost and coverage.

Proper waste planning ensures a smooth installation without tying up excess budget, paving the way to hidden cost analysis.

What Happens When Waste Factors Are Underestimated in Flooring Projects?

Underestimating waste factors compels mid-project material orders that carry expedite fees and increase labor downtime. Installers pause work for additional supplies, eroding productivity and elevating overall project duration by days or even weeks.

How Do Over-Ordering and Under-Ordering Materials Affect Project Budgets?

Over-ordering ties up cash in unused inventory and requires off-site storage or disposal, while under-ordering leads to rush orders, shipping surcharges, and scheduling disruptions. Both extremes inflate budgets beyond initial projections and diminish profit margins.

What Waste Percentages Should Be Applied for Different Flooring Types and Patterns?

Adhering to 5–7 percent for straight-lay laminates and hardwood, 8–10 percent for complex tile layouts, and up to 12–15 percent for ornate patterns prevents shortages without excessive surplus.

What Hidden and Overlooked Costs Commonly Arise in Manual Flooring Estimation?

Beyond materials and labor, estimators often miss subfloor repairs, variable crew rates, disposal fees, and specialty items like underlayment and adhesives. These hidden charges accumulate quickly, turning accurate material estimates into underfunded budgets.

How Do Subfloor Preparation and Unexpected Repairs Increase Flooring Costs?

Subfloor leveling, moisture remediation, and joist repairs introduce additional labor and material expenses that seldom feature in initial quotes. Failing to inspect and price these tasks can add 10–20 percent to total project costs.

Why Are Variable Labor Costs Often Misjudged in Flooring Estimates?

Labor rates differ by region, installer skill level, and job complexity. Estimators who apply a generic per-square-foot labor charge risk underestimating for high-complexity spaces or overpaying for simpler jobs, both of which distort profitability.

What Are the Typical Disposal Fees and Logistics Expenses to Consider?

Disposal of old flooring materials, pallet returns, and transport surcharges each carry flat or per-ton fees that rarely appear in manual takeoffs. Overlooking these logistics costs leaves unexpected invoices that erode net margins.

Which Specialty Items Are Frequently Forgotten in Manual Estimates?

Components such as transition strips, threshold plates, moisture barriers, and vapor retarders are often omitted, only to be added at project execution—triggering budget creep and client disputes.

How Do Manual Estimation Errors Cause Time Delays and Efficiency Losses?

Manual takeoffs can consume hours per project, delaying bid submission and eroding competitive edge. Time lost on remeasurements, quote revisions, and reorders increases overhead and reduces the number of bids an estimator can prepare.

Why Does Slow Bid Generation Hurt Flooring Contractors’ Competitiveness?

Slow turnaround on quotes frustrates potential clients and cedes first-move advantage to faster competitors. In time-sensitive commercial bids, a 24-hour delay can mean the difference between winning and losing a contract.

How Do Project Delays and Rework Result from Estimation Mistakes?

Inaccurate orders force crews to pause work while waiting for corrections or return surplus stock. These interruptions compound schedule slippage, extend labor costs, and strain client relationships.

What Role Does Manual Data Entry Play in Increasing Estimation Time?

Keying measurements and cost data into spreadsheets introduces human error and demands repetitive checking. Automated data transfer dramatically reduces entry time and frees estimators for higher-value tasks.

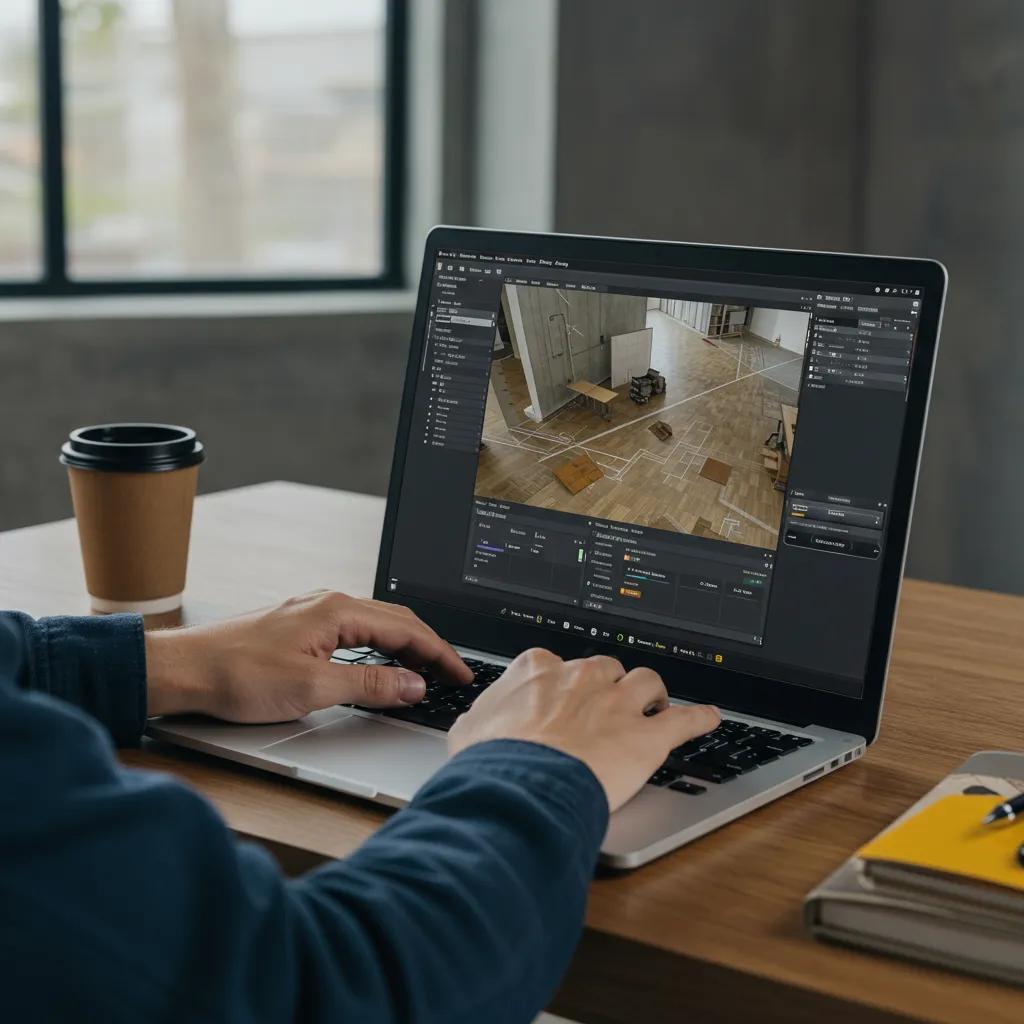

How Can Flooring Estimating Software Prevent Manual Estimation Pitfalls?

Flooring estimating software automates measurement capture, waste calculations, hidden cost rollups, and bid generation to eliminate human error and accelerate project starts. Digital takeoff tools integrate with cost libraries and local labor rates, delivering precise, transparent quotes in minutes.

Which Software Features Address Common Measurement and Waste Errors?

Integrated digital takeoff, automated unit conversions, and pattern-based waste calculators eliminate rounding mistakes and ensure correct material orders on first pass.

How Does Automated Estimation Improve Accuracy and Save Costs?

Automated workflows reduce manual steps by up to 80 percent, cut material overages by an average of 10 percent, and prevent schedule delays due to missing supplies.

What Additional Advantages Does Flooring Estimating Software Offer Contractors?

Beyond error reduction, modern solutions provide centralized cost libraries, real-time labor rate updates, mobile collaboration, and comprehensive reporting that deepens budget insights and strengthens client trust.

Accurate estimation defines project success, and manual methods leave too much to chance. By recognizing measurement errors, waste miscalculations, and hidden fees, contractors can mitigate risks—and flooring estimating software offers a proven path to precision, efficiency, and profitability.

How Does Comp-U-Floor ERP Avoid the Pitfalls of Manually Estimating Flooring Projects?

Comp-U-Floor ERP is revolutionizing the way businesses approach proposal generation and waste management in the flooring industry. Our innovative software seamlessly integrates various aspects of project management, enabling users to create accurate and detailed proposals in a fraction of the time it traditionally takes. By automating key processes and providing real-time data insights, Comp-U-Floor ERP eliminates the common pitfalls that lead to inefficiencies and oversights. This means companies can focus on what they do best—serving their customers—while leaving the complexities of proposal management to the software.

In addition to expediting the proposal process, Comp-U-Floor ERP significantly reduces waste by optimizing resource allocation and project tracking. Businesses can monitor their materials usage and labor costs with unparalleled precision, identifying areas for improvement and minimizing excess. Our software’s ability to produce actionable reports means that decision-makers are equipped with the information they need to make informed choices quickly. For companies looking to enhance their operational efficiency and reduce waste, Comp-U-Floor ERP is the solution they need. Reach out for a free demo today and discover firsthand how this powerful tool can transform your workflow.